All You Need to Know About SMAW Welding

Are you interested in SMAW welding and looking for information on the subject? Our welders are happy to share their extensive expertise in this manual arc welding technique, renowned for its versatility and durability.

In this detailed article, organized by themes, dive into the world of SMAW welding and gain access to a wealth of information validated by industry experts.

What Is SMAW Welding?

SMAW (Shielded Metal Arc Welding) is a fusion welding process. In this method, an electric arc is created between a metal electrode (the rod) and the base material to be welded, generating enough heat to melt both the electrode and the base metal. This process forms a molten pool which, once cooled, creates a strong, durable weld.

Other possible names

- Stick welding: A term widely used in professional and training circles, due to the use of stick-shaped electrodes.

- Flux-cored arc welding: Technical description referring to the flux-covered electrode that generates the shielding gas during fusion.

- Manual metal arc welding (MMA): This term is used mainly in Europe and refers to the manual nature of the process.

These different names all refer to the same technique.

Coated electrodes: the special feature of this type of welding

In SMAW welding, the electrode used is coated with a flux which performs a number of essential functions:

- As it melts with the electrode, the flux releases a protective gas that surrounds the molten bath and shields it from atmospheric contaminants (such as oxygen and nitrogen), which could weaken the weld.

- As it solidifies, the flux forms a layer of slag over the weld, insulating the hot metal from the air and improving the quality and finish of the weld.

- Flux also stabilizes the electric arc, making it easier for the welder to control.

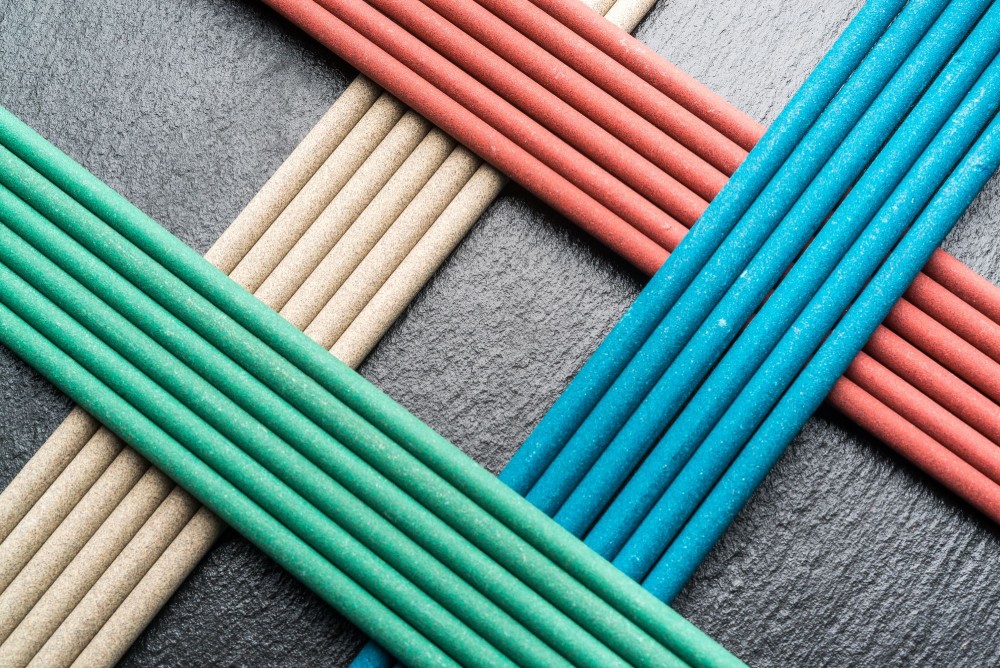

Types of coated electrodes

There are even different types of coated electrodes, allowing welders to choose the best option for their project:

Cellulose electrodes

Rich in cellulose, they offer deep penetration and high welding speeds, ideal for vertical downward welding. However, they generate a lot of hydrogen, which increases the risk of cracking in the heat-affected zone (HAZ).

Rutile electrodes

Containing titanium oxide, they are easy to use and reduce spatter. They are well suited to horizontal and vertical fillet welds, and their slag is easy to remove, simplifying cleaning.

Basic electrodes

Enriched with limestone and fluorine, they provide quality welds and good mechanical properties for medium to heavy sections, but their slag is more difficult to remove and their profile is less clean. But beware, they can be sensitive to humidity.

Iron electrodes

These electrodes are designed for welds requiring lighter penetration. They produce a stable arc and are useful for welding on thinner materials or for repair work.

Metals compatible with SMAW welding

SMAW welding can be used on a wide variety of metals and alloys, making it a highly versatile process. Here are the main materials that can be welded with this arc welding technique:

Mild Steel (or Carbon Steel)

Mild steel is one of the most commonly welded materials using "stick" welding. It is easy to weld and is widely used in structural applications, mechanical fabrication, and repair work.

Alloy steel

Some alloy steels can be welded using the SMAW process, although electrode selection and welding parameters are crucial to avoid cracking and maintain material strength.

Stainless steel

SMAW welding works for certain types of stainless steel. Results are generally superior with electrodes designed to prevent corrosion.

Cast iron

Cast iron is compatible with SMAW welding, although it is often necessary to use specific electrodes (such as nickel-based ones) to minimize the risk of cracking.

Certain nickel and copper alloys

Although less common, some nickel and copper alloys can be welded using specific electrodes adapted to these metals.

Advantages of SMAW welding

Shielded metal arc welding (SMAW) offers a number of advantages that make it one of the most commonly used types of welding in a variety of industrial applications.

Efficient outdoors

The SMAW process is less sensitive to weather conditions than other welding methods (such as MIG welding). The melting of the electrode creates a shielding gas that protects the weld from external contaminants, making it ideal for jobs on site.

Possibility of welding in different positions

Stick welding allows you to weld in any position, whether flat, horizontal, vertical or even at height.

High compatibility

As mentioned above, the SMAW welding process can weld a wide variety of metals.

Weld strength

SMAW welds are robust and durable, with good mechanical properties. The weld metal deposit fuses well with the base materials, providing good structural integrity.

Mobility

SMAW equipment is relatively portable compared with other welding techniques, making it easy to use on building sites or in confined spaces. The process requires no welding gas cylinders, further simplifying transport.

Lower consumables costs

Unlike MIG and TIG welding techniques, stick welding requires no external shielding gas. The flux generates a shielding gas that protects the molten pool from impurities in the ambient air.

Efficient for welding on less “clean” surfaces

SMAW welding enables fast welds, even in the presence of dirt or light rust, where other processes require perfectly clean surfaces.

Precise heat control

Feed rate (speed of travel) and arc length provide effective heat control. This control helps avoid distortion, particularly useful for heat-sensitive metals.

Do You Need Support for a Welding Project?

SMAW welding applications

SMAW welding is used in many industries. Here are some of its main applications:

General industrial applications

It is used in machine shops to assemble industrial components, heavy equipment and various metal structures.

Assembly of metal structures

Effective for assembling beams, columns and other structural steel components. Its outdoor performance, even in windy and dusty conditions, makes it an excellent choice for mobile welders.

Repair and maintenance

Because it allows work to be carried out on slightly rusty or dirty metals, SMAW welding is commonly used for the repair of machinery, construction equipment and metal structures.

Shipbuilding

In the construction and repair of ships and offshore platforms, it is used to weld weather- and salt-resistant steels, often outdoors.

Pressure vessel manufacturing

In the manufacture of gas and steam tanks that have to withstand high-pressure conditions, SMAW welding offers the necessary strength and reliability.

Oil and gas industry

This process is popular for pipeline welding because of its depth of penetration and its ability to produce durable welds in a vertical position and in outdoor environments.

How to arc weld with coated electrodes?

Even if SMAW welding isn’t for everyone, it can be interesting to know what equipment is required and what steps need to be taken to weld with a coated electrode.

Equipment required for SMAW welding

Personal protective equipment (PPE)

The welder must wear gloves, a welding helmet with a tinted visor, and heat-resistant clothing to protect against splashes and intense arc light.

Power source

A welding machine that generates a constant amperage of alternating current (AC) or direct current (DC). It supplies the electric current needed to create the arc between the electrode and the metal workpiece.

Coated electrode

The flux-coated welding rod that melts to produce the weld metal and protect the molten metal. It must be carefully selected.

Electrode holder

A device that holds the electrode firmly during welding and conducts the electric current to it.

Ground clamp

Attached to the workpiece to be welded, it completes the electrical circuit to enable arc formation.

Welding cables

High-capacity cables connect the power source to the electrode holder and ground clamp.

Wire brush

A wire brush with metal bristles is useful for cleaning the surfaces to be welded and removing flux residues or dirt.

Steps to follow for SMAW welding

Surface preparation

Setting up the welding station

Electrode selection and placement

Fitting the ground clamp

Starting the arc

Welding

Cooling and cleaning

Choosing a coated electrode welder

If you’re looking for a welder who can weld with a coated electrode, a few simple checks can help:

Achievements

Choose welders who have already worked on projects similar to yours. Ask them for examples of welding work they’ve done for companies you’re considering hiring.

Training

Although some welders acquire their expertise on the job, academic training is often a guarantee of quality. In Quebec, a number of specialized programs, such as the DEP in welding and fitting, provide a solid foundation for mastering arc welding with coated electrodes.

Accreditation

To ensure work that meets your requirements, opt for an accredited welding service provider. For example, the following CWB certification is an indicator of quality and compliance:

- CWB CSA W47.1 – Fusion Welding of Steel Company Certification

Inspection service

Why not prioritize a supplier who also offers weld inspection services. They’ll have the resources and skills to detect defects, cracks, inhomogeneities or other potential anomalies in your welds.

Omnifab: for impeccable welding work as quickly as possible

In short, SMAW welding requires advanced skills and tools. So, before entrusting a welding project to just anyone, start by making sure their welders are trained and equipped to meet your specific needs.

At Omnifab, we guarantee robust, durable and aesthetically pleasing welds, whether in our welding workshop or on site with our mobile welding unit.

Please do not hesitate to contact us so that we can offer you customized solutions, perfectly adapted to your project.