Electric motors are essential components of many devices and machines used in industrial and commercial sectors, including:

- Electric pumps;

- Compressors;

- Conveyors;

- Machine tools;

- Fans;

- Air conditioners;

- And many more.

When these machines break down, the issue may be caused by a faulty electric motor. The good news is that many types of electric motors can be repaired.

Of course, most electric motor repairs require specialized skills, tools, and replacement parts. That is why most businesses and individuals rely on professionals for electric motor repair and maintenance.

That said, if you are eager to try your hand at reviving an old motor, our team of electric motor repair specialists has written this guide just for you.

In this guide, we will summarize the steps to follow to repair an electric motor, as well as the precautions you should take before tackling this challenge. But first, let’s go over the basics of how electric motors work.

Understanding How an Electric Motor Works

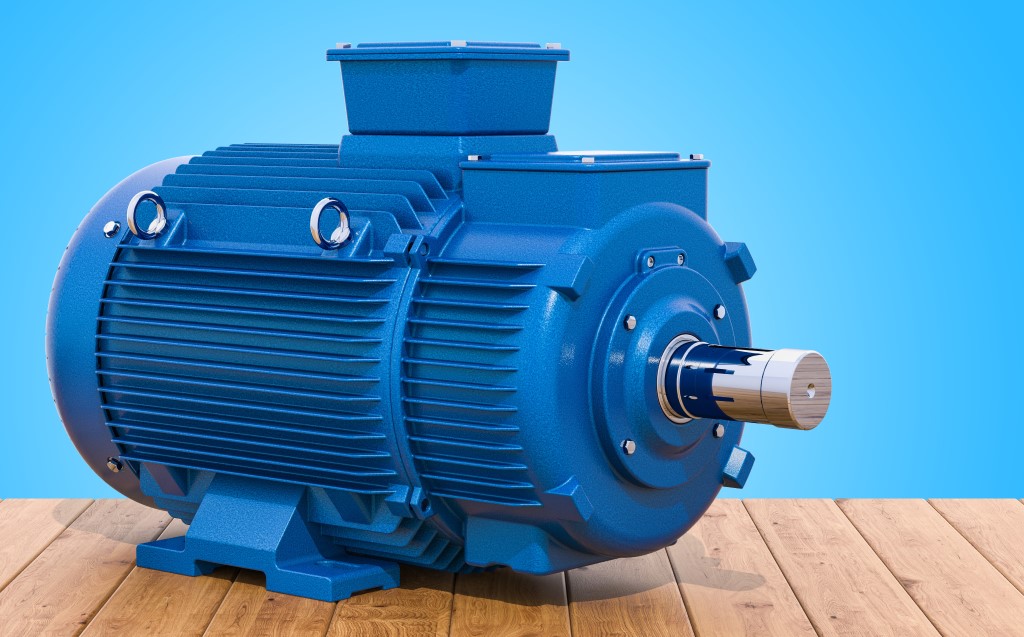

An electric motor is a device that converts electrical energy into mechanical motion. It consists of a stator (stationary part) and a rotor (moving part), both surrounded by a magnetic field. When an electrical current is applied to the stator, it creates a magnetic field that induces another magnetic field in the rotor. These magnetic fields interact, causing the rotor to rotate and generate mechanical motion.

There are different types of electric motors, such as direct current (DC) motors, alternating current (AC) motors, stepper motors, and more. Each has its own characteristics, and understanding them is crucial for effective repairs.

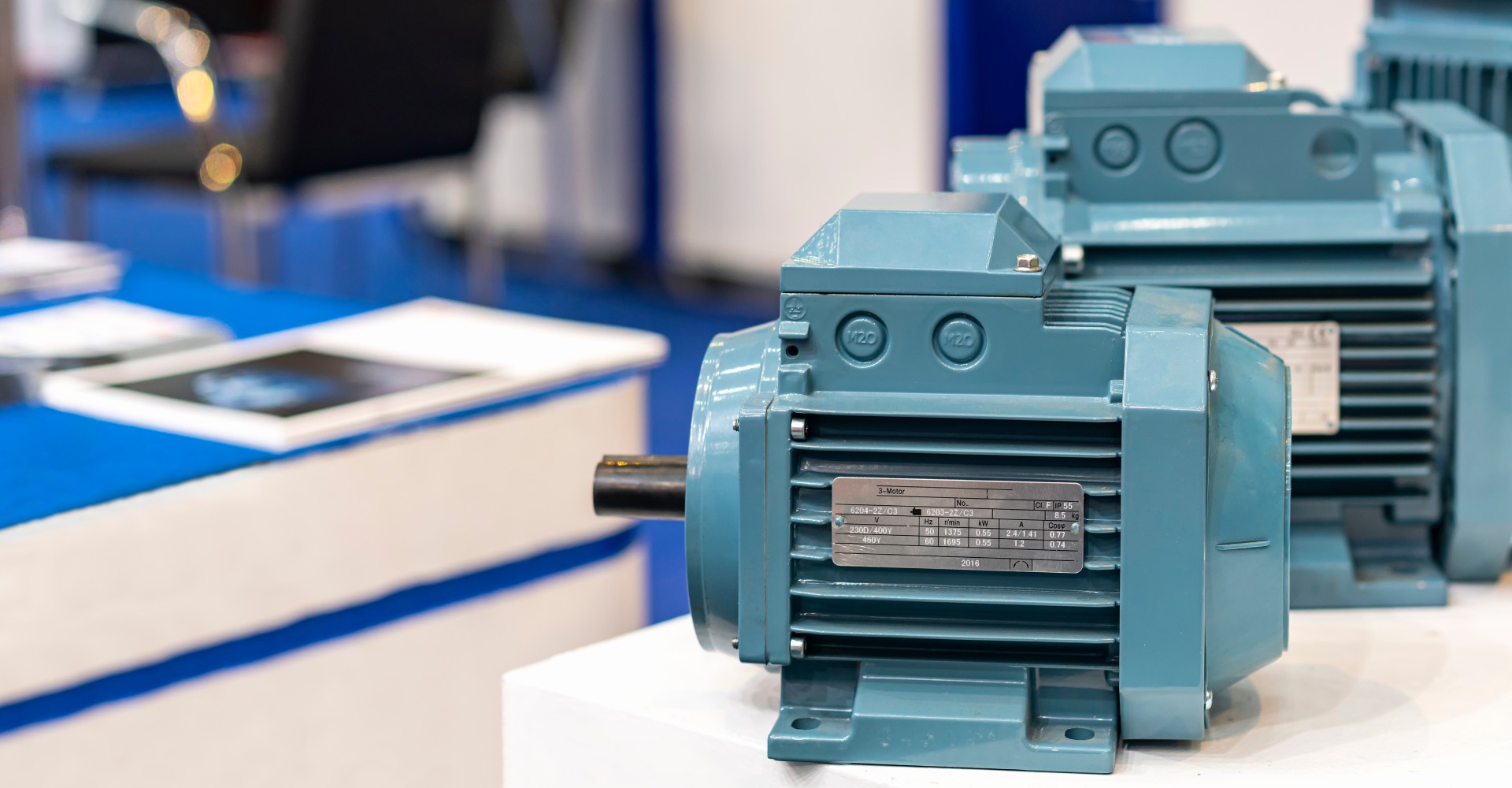

Tip: Check the motor’s nameplate—it contains crucial information about the motor (voltage, frequency, phase, current type, power, etc.). This can be useful if you need to calculate the motor’s efficiency.

Trust Our Experts with Your Faulty Electric Motor

Steps to Repair an Electric Motor

Below are the main steps involved in repairing an electric motor. Keep in mind that these six steps provide only a basic overview.

This guide serves as a general outline, and it is always recommended to entrust this work to qualified professionals.

Also, before you begin, be sure to read the precautionary measures section further down.

Step 1: Identify the Problem

The first step in repairing an electric motor is identifying the issue. Common problems include:

- Unusual noises,

- Overheating,

- Low power output,

- Sparks,

- Vibrations, etc.

By identifying the problem, you can determine the root cause of the failure and the best approach for repairs.

When professionals handle electric motor repairs, they conduct a thorough investigation using specialized instruments to assess the condition of various motor components (e.g., analyzing shaft alignment).

Step 2: Open the Electric Motor

After identifying the problem, you will usually need to open the electric motor to inspect the internal components.

For this, you will need a screwdriver, pliers, and other tools. If you are unsure how to open the motor, seeking professional assistance may be a good idea.

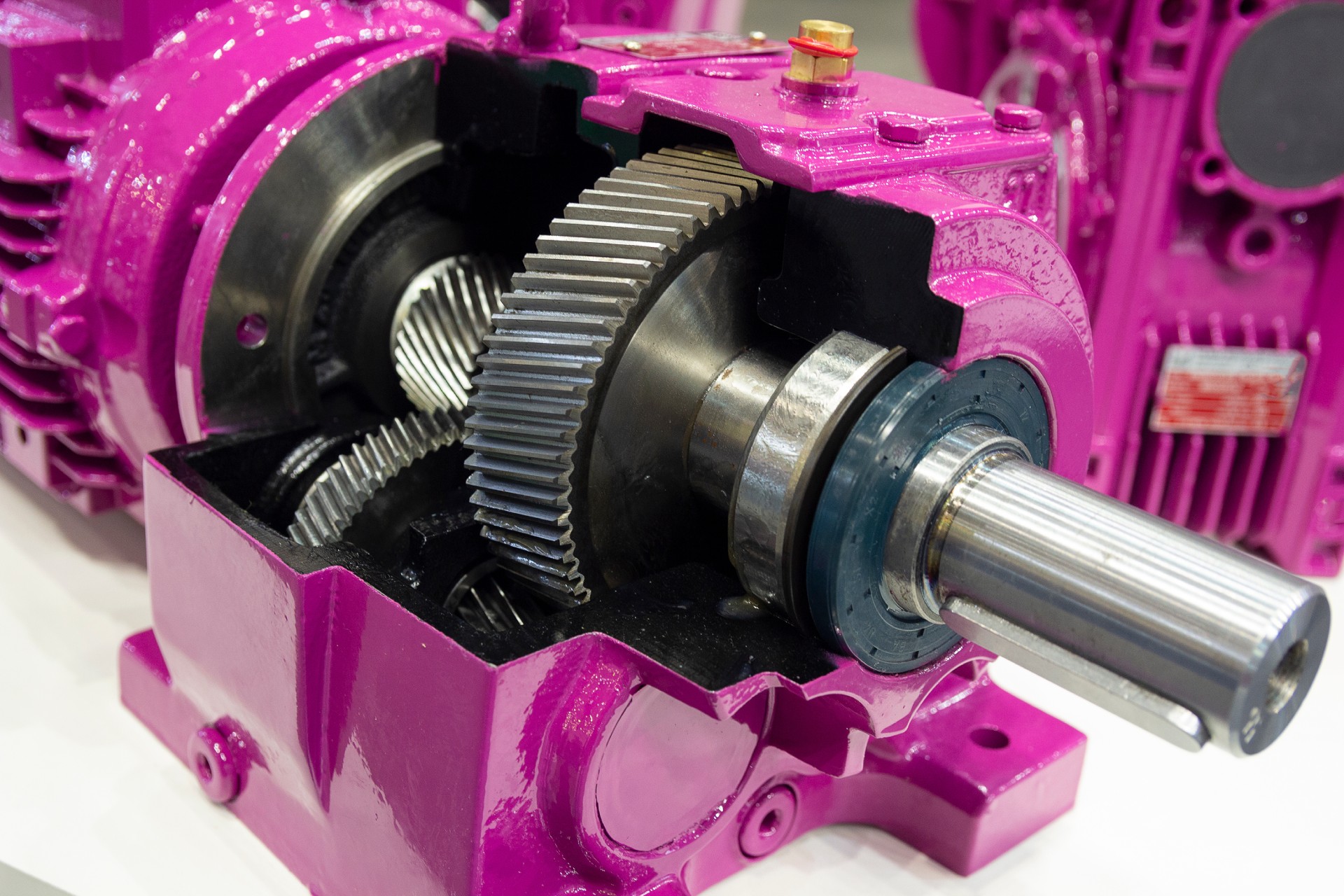

Step 3: Examine the Internal Components

Once the motor is open, inspect the internal components to determine the cause of the issue. Key components to check include:

- Carbon brushes,

- Commutator,

- Bearings,

- Rotor,

- Stator,

- Capacitor,

- Solder joints and electrical contacts.

Taking photos or noting the position of components before removing them can help with reassembly.

Keep in mind that some component failures are not visually detectable. Many issues require measurement tools, such as a multimeter, for proper diagnosis.

Step 4: Replace Faulty Components

Once defective components have been identified, it is time to replace them. Use high-quality parts compatible with your motor model. Spare parts can be purchased from the original manufacturer or specialized stores, or they can be machined to reduce lead times.

Some motor components can be refurbished by experts. For instance, rewinding (also known as re-coiling) is sometimes an option to repair an electric motor.

Step 5: Reassemble the Electric Motor

After replacing the faulty components, reassemble the motor.

Ensure that all components are placed correctly. If necessary, refer to the photos or notes taken during disassembly.

Step 6: Test the Electric Motor

Once the motor has been reassembled, test it to ensure it is functioning correctly. Connect it to a power source and check for signs of overheating, unusual noises, or other issues.

If everything runs smoothly, you have successfully repaired the electric motor.

Precautions When Repairing an Electric Motor

Before repairing an electric motor, take the following precautions to ensure safety and prevent damage.

Check the Motor’s Warranty

In most cases, opening an electric motor under warranty for self-repair will void the warranty. Most motor warranties specify that they are invalid if the motor is opened or repaired by an unauthorized party.

Disconnect the Power Supply

Before working on the motor, ensure it is completely disconnected from any power source. This minimizes the risk of electric shock or motor damage.

Wear Protective Gear

When working on an electric motor, wear protective equipment such as safety glasses, insulated gloves, and protective clothing to avoid injury.

Discharge the Capacitors

Capacitors store electricity even after the motor is unplugged. It is crucial to discharge them before working on the motor.

You can do this by using an appropriate discharge resistor or by shorting the capacitor terminals with a screwdriver.

Use the Right Tools

Only use appropriate tools for electric motor repairs. This helps prevent damage to the motor’s internal components.

Follow the Manufacturer’s Instructions

Before repairing an electric motor, consult the manufacturer’s instructions, as they can vary significantly between different motor models.

How to Repair an Electric Motor? Conclusion

Ultimately, repairing an electric motor is a task best handled by an expert. However, by following the steps outlined above, you may be able to resolve the issue yourself—but be prepared to exercise patience and caution.

To avoid complications, you can also reach out to our electric motor repair service. Many businesses across Mauricie, Lanaudière, Montreal, and other regions in Quebec trust Omnifab for their electric motor repairs and for purchasing new electric motors.