What Is Process Mechanics?

In industrial production jargon, a process is a series of interdependent tasks that transform inputs into a finished product. But what exactly does process mechanics mean in this context?

This article provides a clear definition, along with additional insights to help you better understand what process mechanics is and why it matters.

Definition of Process Mechanics

Process mechanics—sometimes also referred to as mechanical process engineering or process engineering—is a discipline rooted in applied mechanics and engineering. It focuses on developing, analyzing, and optimizing industrial processes. Its primary goal is to improve the efficiency, safety, sustainability, and profitability of industrial operations.

It encompasses the study of mechanical systems used in material transformation and product assembly. This includes system design, fabrication, operation, and maintenance—all of which are core competencies we offer in-house at Omnifab.

Optimize your industrial processes with a turnkey solution

Where Is Process Mechanics Applied?

Process mechanics plays a key role in various industries, including:

- Petrochemical industry: Oil refineries, petrochemical plants

- Food and Beverage: Farms, food processing plants, beverage production facilities

- Metallurgy: Steel mills, foundries, aluminum production

- Water Treatment: Water treatment plants, wastewater facilities

- Raw Material Processing: Pulp and paper mills, carton and lumber production

That said, many other sectors also rely on process mechanics to improve their operations.

The Process Mechanical Engineer

Industrial businesses looking to improve their processes often turn to a process mechanical engineer (or process engineer). This expert plays several key roles for their clients:

Process Design

Defining the steps and conditions required to transform raw materials into finished products.

Equipment Design

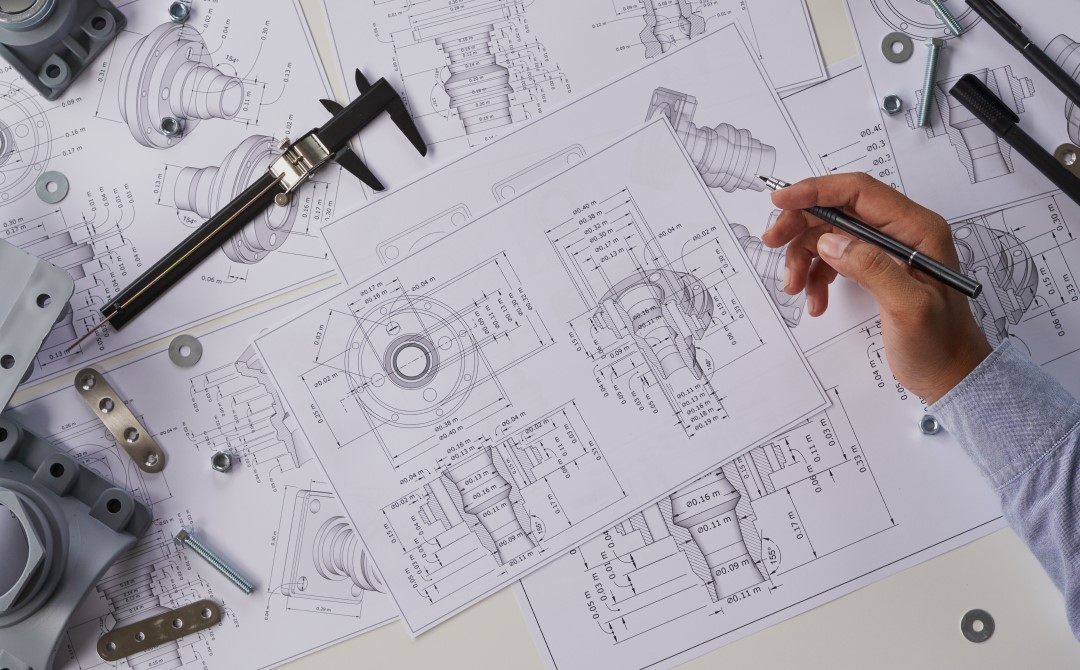

Selecting and designing the necessary production equipment such as pumps, transmissions, conveyors, application systems, and more.

System Integration

Ensuring the entire system is compatible, efficient, and coherent—accounting for how each component interacts.

Project Management

Planning, organizing, and directing projects while meeting budget, timeline, quality, legal, and regulatory requirements.

Troubleshooting

Identifying and resolving technical issues that arise during system operation.

Key Skills of a Process Mechanical Engineer

A skilled process mechanical engineer combines technical expertise with broader competencies to design, analyze, and optimize industrial processes. Core skills include:

- Fundamental Sciences:

- Mass and Energy Transfer: Understanding how materials and energy flow and transform within systems.

- Fluid Dynamics: Studying how fluids behave and move within process systems.

- Solid Mechanics: Analyzing stress and deformation in solid materials used in process equipment.

- Process Control: Technologies and methods for monitoring and managing process parameters to ensure quality and efficiency.

- Mechanical Design Tools: CAD/CAM software, simulation tools, data analysis techniques, 3D scanning, and more.

- Sustainable Development: Ability to assess environmental impacts and develop strategies to minimize them (waste reduction, reuse, recycling, etc.).

- Industry Standards and Regulations: Knowledge of safety, environmental, and quality standards relevant to each sector.

Thanks to this diverse skill set, process mechanical engineers can design and manage industrial systems that are efficient, safe, and sustainable—while meeting economic and regulatory demands.

Omnifab: Your Go-To Partner in Process Mechanics in Québec and Across Canada

In summary, process mechanics is an ever-evolving field driven by technological advances and growing demands for efficiency, sustainability, and safety.

Process engineers play a crucial role in developing innovative technologies and improving industrial performance.

Want to know how our team can help optimize your operations? Don’t hesitate to contact us to share your goals—we’ll work with you to develop a personalized turnkey solution that meets your needs.