How Does a Blue Laser 3D Scanner Work?

The process of 3D scanning using a blue laser scanner involves several steps:

1 – Positioning the sensors (targets)

Magnetic sensors are strategically placed on the part or machine to be scanned (no more than 12″ between targets). If the object to be scanned is not magnetic, the sensors are attached to the surface with a temporary adhesive.

2 – Laser Beam Projection:

The scanner emits a blue laser beam onto the surface of the object being scanned. This laser is projected in the form of a grid of lines that deforms according to the geometry of the object.

3 – Image Capture:

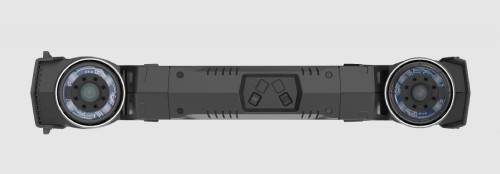

Sensors on the scanner capture images of the object with the projected laser mesh. They record deformations and variations in the laser beams resulting from the characteristic shape of the scanned object.