In the industrial sector, various types of equipment have been developed to transition from a computer model to a physical object. For example, CNC machine tools and, more recently, 3D printers. But did you know there is a technology that allows you to work in the opposite direction? This technology is 3D scanning.

In the following paragraphs, we will demystify 3D scanning by exploring the many aspects of this fascinating and versatile technique.

What is 3D Scanning?

3D scanning is the process of capturing the geometry of an object or physical environment and converting it into a three-dimensional digital model. This digital representation can then be viewed or edited using specialized software.

This three-dimensional modeling is achieved using devices, commonly referred to as 3D scanners, that collect data on the shape, size and texture of an object from multiple perspectives.

Introducing 2 Types of 3D Scanners

There are several types of 3D scanners that can be used to create detailed three-dimensional models of physical objects. They include structured light scanners and laser scanners.

Structured Light 3D Scanners

Structured light 3D scanners use trigonometric triangulation to create the digital object. In other words, they project a series of patterns (dots, lines, or point clouds) onto an object, and then built-in cameras capture the deformations of light caused by contact with the relief of the scanned object.

These devices are typically designed for 3D scanning of objects ranging in size from 0 to 3 meters (10 feet). Their accuracy is extremely high (0.250 mm/m, down to 0.1 mm).

Laser 3D Scanners

3D laser scanners also use triangulation technology to accurately calculate the dimensional characteristics of an object. However, they project a grid of laser lines rather than light patterns. This makes them particularly well-suited for bright environments, such as outdoors use.

The laser “grid” projected onto the surface of the object being scanned deforms to reveal its unique geometry. The device’s sensors then calculate the position of each point to produce a three-dimensional image with even greater accuracy than that of the structured light scanner (on the order of 0.075 mm (0.0030 inch)). Some of these devices also require the application of small magnetic “targets” to the surfaces of the part being scanned to increase the accuracy of the triangulation.

In general, laser scanners are better suited for industrial use because their superior acquisition speed allows them to scan large objects in much less time. At Omnifab, for example, we use a laser scanner that can scan objects as large as 15 meters (50 feet) in size. However, different scans can be combined to scan even larger objects.

Another significant advantage of laser 3D scanners over structured light 3D scanners is their ability to scan shiny, oily and reflective surfaces without the need for prior preparation. For example, it may be necessary to spray glossy surfaces with temporary paint before scanning with a structured light device. The laser scanner eliminates this tedious process.

Use our 3D scanning service

Some Applications of 3D Scanning

3D Scanning has a wide variety of applications. Here are some of the most common:

1. Design and Prototyping

This technology makes it possible to create accurate models of parts or products, facilitating design, prototyping, and new product development.

2. Reverse Engineering

3D scanning enables the creation of models from existing physical objects, which proves to be highly practical for reverse engineering and modifying existing parts.

3. Quality Control

3D scanning allows the manufactured object to be compared to the CAD model during the design phase. In this way, it is possible to check and verify conformity in terms of dimensions, volumes, surfaces, etc. Using a 3D scanner means you can make extremely reliable measurements!

4. Product Customization

3D scanning allows products to be customized to meet specific customer requirements. Modifying a computer model requires far fewer resources than producing different “physical” versions of a part.

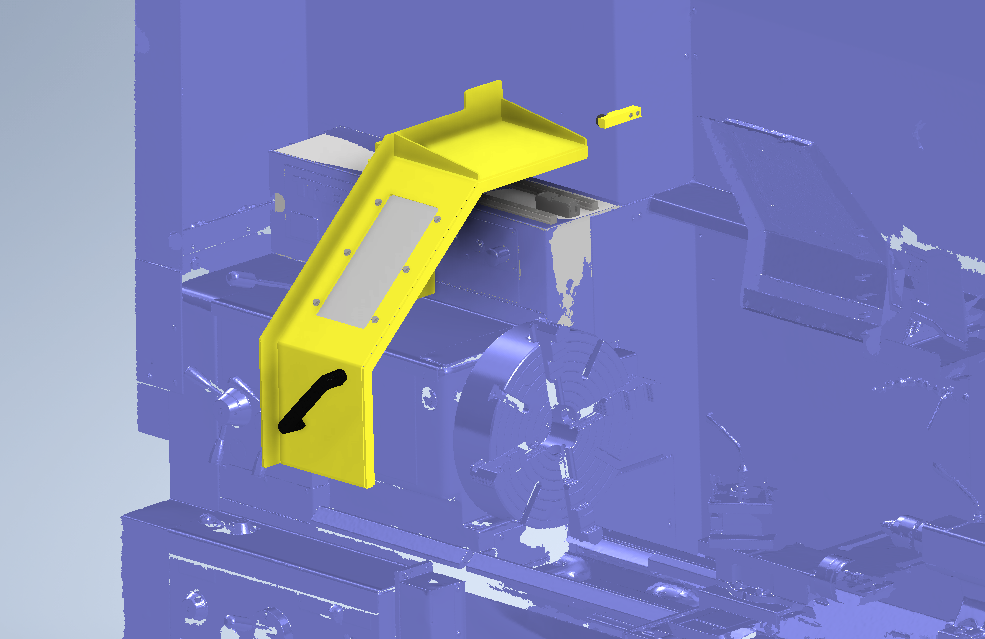

5. Securing Equipment

The design and installation of safety devices on hazardous machinery is facilitated by 3D scanning. In fact, a 3D scan can be used to design custom parts that are 100% compatible with the equipment being secured.

6. Archiving

Creating detailed 3D models and point clouds provides complete documentation of a company’s assets and products.

What can WE do with it?

At Omnifab, we offer a 3D scanning service at our factory or directly at your site, which is especially convenient when the item to be scanned is difficult or impossible to transport.

We can therefore use it for all these industrial applications:

- Reverse engineering

- Reproduction of parts

- Improvement or modification of existing objects

- Machine safety

- Development of production tools

- Inspection, verification, and quality assurance

- Simulation and testing

- Archiving

- And much more!

Industries That Benefit Most From 3D Scanning

3D scanning technology offers significant benefits to a wide range of industries. Here are some of the industries that benefit the most and examples of how they use it:

Manufacturing and Industrial Production: Allows parts to be digitized for reverse engineering, quality control and production process optimization.

Aerospace: For inspection, reverse engineering, and maintenance of complex, often safety-critical parts.

Automotive: Used for prototyping, part design, quality inspection and component performance analysis.

Healthcare and Medical: Essential for creating custom prosthetics, 3D printing organs for educational purposes, and surgical planning.

Architecture and Construction: For digitizing existing buildings, managing renovation projects, and creating Building Information Modeling (BIM) models.

Cultural Heritage and Museums: For conservation, restoration, and reproduction of historical and artistic artifacts.

Education and Research: Used to create educational models, conduct engineering research, and explore scientific concepts.

Electronics and Telecommunications: For rapid prototyping, complex circuit design, and high-precision component assembly.

Anticipate the Post-Processing Time Required

The time required to process the images captured by a 3D scanner generally depends on the intended goal.

- If the goal is to design a part that fits the scanned object, there will be very little post-processing required. For instance, if you want to add a safety guard or other device to a machine and ensure that it is 100% compatible with the machine, the post-processing time required is minimal.

- If the goal is to create a mold to manufacture or reproduce the scanned part, more post-processing will be necessary to create a perfect theoretical model. This is because the technician must eliminate all the “noise” from the initial scan (scratches, dust, wear from use, manufacturing tolerances, etc.), which takes some time.

- If the goal is to create a native 3D model (such as an Inventor or SolidWorks file) that can be used to track changes in the object’s geometry, the part will need to be redrawn and the result compared to the scanned file. This is the most time-consuming post-processing scenario.

Take the Leap into 3D Scanning with Our Experts

At Omnifab, we make sure to adapt to your needs. Therefore, once the scanning is complete, we can transfer the file to you in the format that suits you best. With just a few clicks, you can transfer your 3D models to virtually any industrial drawing or CAD software.

Feel free to contact us for any questions and projects requiring 3D scanning.