What is industrial mechanics?

If you ask anyone you know who works in industrial mechanics to describe their job, chances are everyone will tell you something different. The reason is quite simple: industrial mechanics is an industry in which specialists from many disciplines work on a variety of tasks and projects.

So, who better than a multi-disciplinary team like ours to explain what industrial mechanics is all about, combining points of view and informations from multiple fields of expertise.

Definition of industrial mechanics

In its “classic” definition, industrial mechanics is often presented as the set of activities, methods and techniques related to structures, machines, mechanisms or devices for producing or transmitting motion, force or deformation, and which are used in an industrial context.

The people who work in this sector are known as industrial mechanics.

Different fields of industrial mechanics

The industrial mechanics sector covers a number of different branches that are involved at specific points in the life cycle of industrial structures and machines.

Some of the tasks associated with these fields of expertise are always performed on the industrial mechanics company’s own premises, while others will be conducted on the customer’s sites by an external industrial mechanics team.

Some companies even offer industrial mechanics labor rental, a practical subcontracting solution for large-scale mandates.

Mechanical engineering

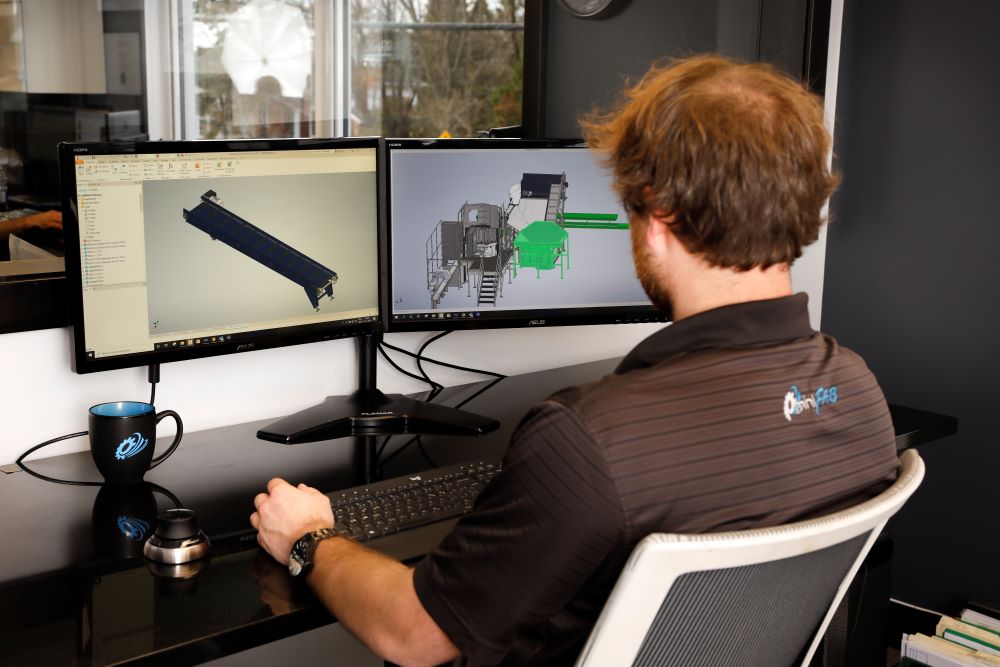

Mechanical engineering involves the development, prototyping, and design of machines or parts, taking into account various constraints (measurements, compatibility with existing systems, safety standards, productivity goals, etc.).

Mechanical engineers can also improve the performance or safety level of production equipment by proposing various mechanical modifications and machine automation solutions.

To express and share their vision as effectively as possible, engineers commonly use computer-aided design (CAD) software. They may also benefit from technologies such as 3D scanning.

Mechanical manufacturing

Basically, mechanical manufacturing consists of producing the parts and components needed to keep industrial equipment running smoothly, using a variety of materials (sheet metal, blocks, rods, plastic, etc.) chosen according to their properties.

This branch of industrial mechanics requires a high degree of rigor, as well as sophisticated tools that enable extremely high levels of precision to be achieved, even when manufacturing voluminous parts.

Activities such as machining (which includes various CNC and traditional machining operations), welding, plasma cutting, laser cutting, oxy-fuel cutting, and metal bending are all part of industrial mechanical manufacturing. Surface treatments like chemical blackening can also be included in this category.

Assembly and installation

Only when correctly assembled that the parts become solid structures or machines capable of performing industrial tasks. This process is conducted by mechanical assemblers.

Machines can be assembled or mounted at the manufacturer’s premises or at the customer’s premises (in his factory, on his building site, or anywhere else he chooses).

Installation involves connecting the machines to various networks (electricity, compressed air, plumbing, IT, etc.) and calibrating them.

Care and maintenance

The purpose of industrial equipment servicing and maintenance is to ensure optimal operation. This may involve dynamic balancing and vibration analysis, cleaning or lubricating certain components, or replacing parts with a limited lifespan.

Some machines need to operate day and night, to ensure continuity of operations and the achievement of business objectives. A good preventive maintenance plan, including regular inspections and interventions, also helps reduce the risk of mechanical breakdown and premature wear of parts.

Machinery and equipment repair

Despite rigorous maintenance, mechanical problems can affect industrial equipment and prevent it from operating properly.

The repair of malfunctioning machinery generally begins with a diagnosis based on the symptoms detected, the technical documentation available on the machine and its use. An intervention strategy is then deployed to get the machine back up and running as quickly as possible.

Sometimes, it’s even possible to completely refurbish a machine.

Get fast help from our industrial mechanics specialists

Industry sectors that benefit from industrial mechanics

Many types of companies work closely with industrial mechanical specialists to maintain and optimize their production equipment. Here are some examples of sectors where industrial mechanics play a vital role:

Industrial Sector Companies

Manufacturing companies rely on industrial mechanics for the fabrication of machine parts, equipment maintenance, and the implementation of automated production lines.

Agricultural Sector Companies

In agriculture, industrial mechanics are essential for building and maintaining heavy machinery, as well as automated crop management systems.

Mining Sector Companies

Mines depend on industrial mechanics to maintain and repair heavy equipment such as excavators, mining trucks, and crushers, ensuring continuous and safe production.

Food Processing Sector Companies

Food processing plants use complex mechanical systems for production lines, packaging, and quality control processes.

Petrochemical Sector Companies

Petrochemical facilities require maintenance services for their oil and gas production, refining, and chemical processing equipment, including pumps and compressors.

Metallurgical Sector Companies

In metallurgy, industrial mechanics are involved with smelting equipment, rolling mills, metal machining, and the maintenance of production equipment such as furnaces and hydraulic presses.

Transportation Sector Companies

Transportation companies—whether rail, maritime, or air—rely on industrial mechanics for the repair and maintenance of complex equipment, including engines, transmission systems, and speed control systems.

Pulp and Paper Sector Companies

Industrial mechanics are also essential in sectors such as pharmaceuticals, energy, construction, and other industries where machines and equipment must operate at peak performance.

And many more!

Industrial mechanics are also essential in sectors such as pharmaceuticals, energy, construction, and other industries where machines and equipment must operate at peak performance.

Advantages for companies of having a partner in industrial mechanics

For these companies, there are many advantages to being able to count on an industrial mechanics partner like Omnifab. Here are just a few of them:

Greater safety

When a machine is not working optimally or is not properly secured, it can create dangerous working conditions for its operators.

By working closely with specialists in industrial equipment maintenance and machine safety, organizations can avoid many workplace accidents.

Improved productivity

An industrial mechanics partner can help a contractor set up a customized maintenance program for its production equipment.

This can include routine maintenance, such as inspections, adjustments, oil and fluid changes, parts replacements and more. These interventions enable the machinery to operate much more efficiently, while consuming less energy.

Reduced downtimes

In a production company, any unplanned downtime can translate into significant financial losses.

Having a dedicated industrial mechanics partner is the best way to ensure rapid service in the event of an urgent problem with a machine.

What’s more, less urgent interventions can be scheduled during shutdowns, so as not to impact production activities.

Equipment used in industrial mechanics

There’s really no limit to the number of tools used by industrial mechanics. Depending on the task in hand, there is always a piece of equipment that will complete it with minimum effort and maximum precision.

However, it should be pointed out that many tools can only be handled by workers with specific skills.

Here are just a few of the tools that can be part of an industrial mechanic’s toolbox.

Examples of basic mechanical tools

- Wrenches (Allen, impact, socket, adjustable, etc.)

- Pliers (“Vise grip”, “long nose”, etc.

- Screwdrivers

Examples of measuring tools

- Micrometer

- Caliper gauge

- Limit gauge

- Laser level

- Voltmeter

- Laser alignment

- CMM inspection machine

- 3D Scan

Machining and cutting equipment examples

Welding equipment

- Welding flashlight

- Arc welding station

- Soldering iron

- Welding gun

- Welding gas

Becoming an industrial mechanic

In Quebec, people wishing to become industrial mechanics can follow a training program that provides them with the knowledge, skills and attitudes they need to practice this trade.

Specialized training at both the technical and university levels is of course available to those wishing to pursue advanced studies and specialize in a particular field, but it is the Industrial Mechanics for Construction and Maintenance course that is the most common way to enter the profession.

This program of professional studies (DEP) lasts approximately 1,800 hours and is offered at many educational institutions in Quebec.

Program goals

At the end of their training, students will have an understanding of electricity, electronics, electromechanics, welding, piping, machining, vibration analysis and automation.

These skills enable them to:

- Install, maintain and perform various types of industrial maintenance, repair, troubleshoot and modify mechanical systems of all kinds (hydraulic, pneumatic, electrohydraulic, electropneumatic and others) assisted by computers or programmable logic controllers.

- Participate in the assembly of production line equipment or plant start-ups

- Work with equipment or systems such as pumps, presses, industrial fans, variable speed drives and reducers, compactors, compressors, electric motors, handling equipment, lifting device and industrial production machinery.

- Les perspectives de carrière en mécanique industrielle

Career opportunities in industrial mechanics

Job prospects for industrial mechanics graduates are currently excellent. Many organizations in the sector have positions to fill on their teams.

Working at Omnifab

If you’re interested in a career in industrial mechanics or a related discipline, we even invite you to send us your CV! You could become part of our dynamic team and enjoy a stimulating work environment and numerous benefits.

Omnifab: a unique approach to industrial mechanics

Within our company, we value all areas of industrial mechanics. We firmly believe that mastery of each of them is what enables us to offer turnkey services of impeccable quality, with no subcontracting and the shortest lead times in the industry.

So if you’re looking for an industrial mechanics partner who can help you achieve your goals, put your trust in our multidisciplinary team.