A laser is a highly concentrated, amplified light. The term “laser” stands for “Light Amplification by Stimulated Emission of Radiation”, a technology developed in the 1960s.

Thanks to numerous technological advances, lasers are now used in a multitude of processes.

One of these uses is laser cutting, a process used in our factory and about which you will learn a great deal as you read this text. In the following paragraphs, you’ll find information about how it works, its applications, its benefits and much more! But why not start with its definition?

A brief definition of laser cutting

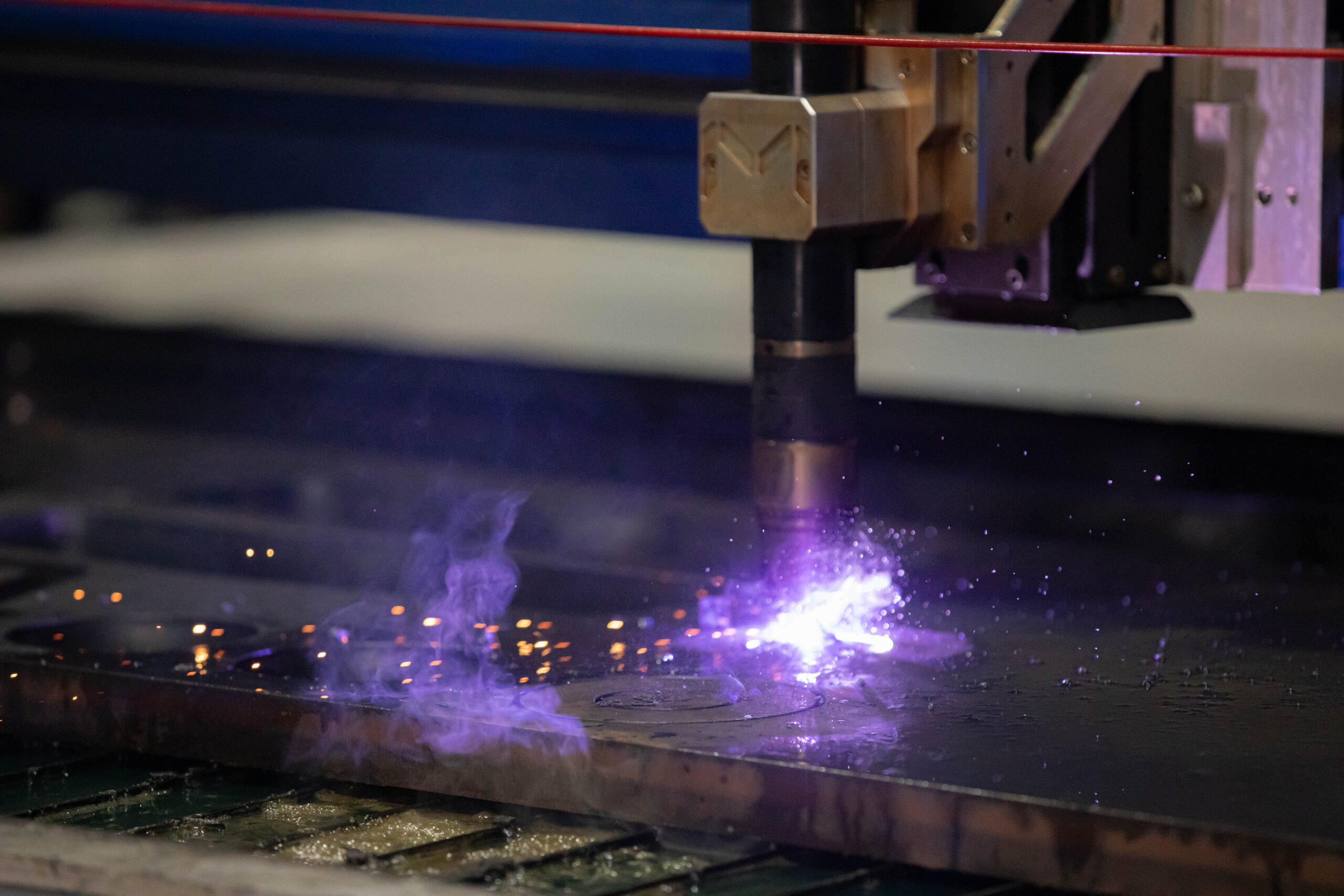

Laser cutting is a subtractive manufacturing technique in which materials are cut or engraved using a powerful, high-precision laser focused on a small area. Focusing the laser beam on the reduced area raises the temperature of the material until it melts or vaporizes.

Most of the time, a computer is used to direct the laser and plot the cutting path according to a plan downloaded into a software program.

This process is mainly used on industrial production lines and in mechanical engineering and machining workshops, but as it becomes more and more accessible, it can now be found in many other sectors.

Laser cutting should not be confused with oxy-fuel or plasma cutting.

Give our experts a laser cutting job today

How does a laser cutter work?

Laser cutting is generally performed using a computer-controlled machine (CNC).

Inside the machine, the laser beam is created by stimulating lasing material with electrical discharges or lamps within an enclosed space. The lasing material is then amplified by internal reflection until it has sufficient energy to escape as a stream of monochromatic light.

This intense light is then focused on the work area by mirrors or optical fibers, which direct the beam through a lens to intensify it. The laser beam then burns, melts or vaporizes the material locally to achieve the desired result. The type of material a laser can cut depends on the type of laser and the power of the machine.

Despite what the name might suggest, it’s not uncommon for a laser cutting machine to perform several different operations: cutting, engraving and marking.

Cutting

When the laser beam passes completely through the material, it creates a cut.

A laser cut is generally very precise and clean, but the appearance of the cut edges depends on the material and its thickness.

The engraving process

Engraving is when the laser beam removes parts of the material, but does not cut the entire material.

Marking

Marking is when the laser does not remove the material, but changes its color, for example.

Examples of laser cutting applications

Laser cutting is often used for prototyping and manufacturing large metal parts, especially flattened shapes, whose dimensions need to be very precise.

It is particularly effective in sectors where the pace of production must remain high:

- Architectural metalwork;

- Cutting of metal signs;

- Manufacture of a wide range of industrial equipment;

- Machinery manufacturing;

- And many others.

In short, where traditional manufacturing processes impose constraints, laser cutting offers greater design freedom and facilitates large-scale production.

The advantages of laser cutting

Overall, laser cutting offers several advantages when compared to traditional cutting techniques:

- A very high level of precision;

- Material savings;

- Higher production speed;

- Extremely clean edges;

- Minimal material deformation;

- High levels of process reliability.

Materials that can be laser cut

Most materials can be cut with a laser beam: metal, wood, textiles, paper, cardboard, ceramics, acrylics, composites, leather, glass and more. Specific wavelengths have been developed for optimized rendering on each type of material.

It’s safe to assume, however, that cutting metal sheets is the most widespread application. For example, sheets of steel or stainless steel up to 1 1/4″ thick can be laser cut.

However, some materials have reflective properties that complicate their response to laser cutting. This is the case, for example, with silver and copper.

Omnifab: growing expertise in laser cutting

In short, laser cutting is a manufacturing process that is increasingly used by industrial mechanical manufacturing companies.

At Omnifab, we don’t hesitate to use this technique to create all kinds of parts and components for the machines we custom-design. We even offer a laser-cutting service designed to meet corporate needs.

Don’t hesitate to contact us to find out more!