There are a multitude of processes for shaping metals to the desired form. One of them is metal bending.

In the following paragraphs, you’ll find information on applications, methods, equipment and many other aspects of metal bending! But first, let’s define exactly what we mean by “metal bending”.

What is metal bending?

Metal bending is the process of shaping metal plates or sheets into a predetermined shape by applying a significant force. This force exerts a constraint greater than the metal’s elastic limit, enabling the material to deform physically without breaking or shattering.

To achieve this, the metal is usually placed in a machine called a press brake, between a punch and a matrix. The punch is the moving component and the matrix is the fixed tool, which can take a variety of shapes (e.g. “U” or “V” matrix).

Metal bending applications

Metal bending is often used to manufacture parts with precise angles, from a sheet or plate of metal.

It’s a technique that has proved its worth, especially in sectors where production rates must remain high:

- Architectural metalwork and sheet metal work;

- Manufacture of a wide range of industrial equipment;

- Machinery manufacturing;

- And many others.

Use our fast, professional metal bending service

Different metal bending methods

There are several methods of metal bending. To determine which one will deliver the desired results, it’s important to know the specifics of each.

Here are the most commonly used:

V-folding

V-bending is the most common method of metal bending. As the name suggests, the V-bending method uses a V-shaped matrix and a punch to bend metals to the desired angles.

During the V-bending process, the punch forces the metal plate into the V-shaped slot of the matrix, enabling different bending angles to be achieved. For example, you can obtain acute, obtuse or 90° bending angles, depending on the angle of the V-shaped punch and the matrix.

Air bending (sometimes called partial bending)

Air bending is quite similar to the V-bending method. It too relies on a punch and a V-shaped matrix to bend metal sheets.

However, unlike conventional V-bending, the air-bending punch does not force the material into the bottom of the matrix cavity. Instead, it leaves space (or air) beneath the sheet.

In other words, the equipment only touches the material at three points: the punch and the matrix shoulders.

Bottom bending (sometimes called bottoming)

Bottom bending is another bending technique similar to V-bending. It differs from the latter in that an additional force is applied by the punch tip after the bend is complete.

This additional force enables us to better control the springback phenomenon (discussed later in the text).

Wipe-folding

In the wiping bending method, the sheet is held against a wiping matrix by a pressure pad. The punch then exerts a force on the edge of the sheet that extends beyond the matrix and the pressure pad, causing it to bend over the end of the matrix.

Rolling

Rolling forms pieces of metal into coils, cones or curved shapes. This unique metal-forming process usually requires the use of a machine called a rolling machine.

U-bend

All in all, U-bending is very similar to V-bending. The main difference is that this method produces a U-shape in the metal rather than a V-shape.

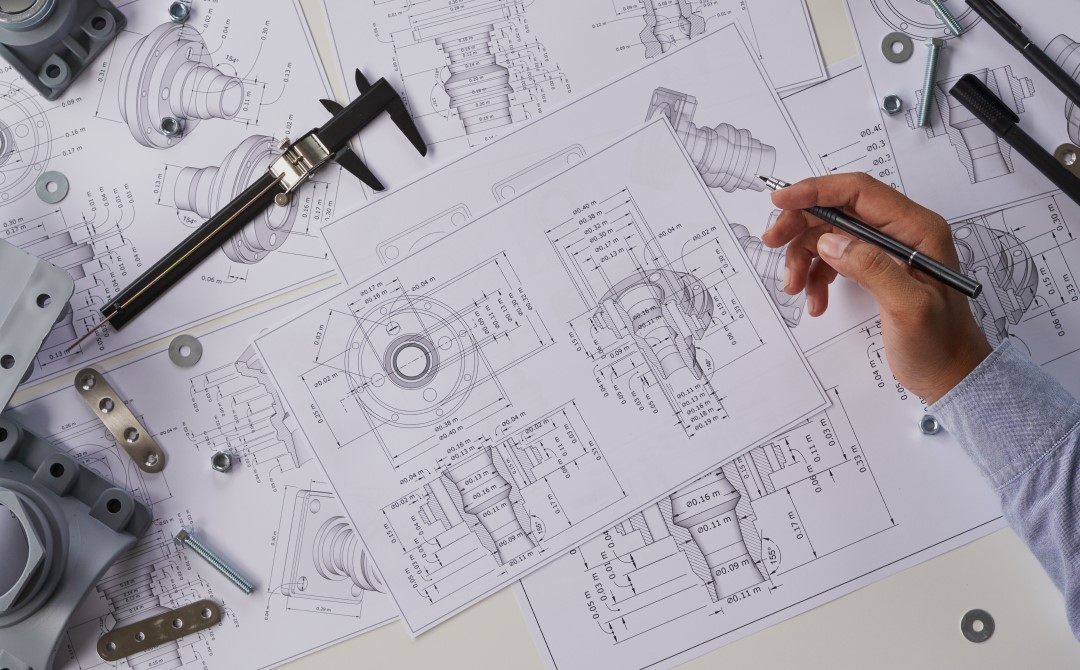

Metal bending equipment

Most metal bending operations are carried out using two different machine tools: the press brake and the rolling machine.

The press brake is used to create precise angles in metal sheets or plates, while the rolling machine is used to give a rounded shape to metal parts such as tubes, bars or profiles.

Metals well suited to bending

Most metal bending companies can work with several different metals. These include:

- Steel;

- Stainless steel

- Galvanized steel

- aluminum

- copper;

- Brass

Springback: a physical phenomenon associated with metal bending

Springback is a geometric change that occurs at the end of the metal bending process, more precisely when the forces applied to the part are released.

In other words, freshly bent parts tend to return to their original shape, which can affect their dimensional accuracy.

Fortunately, there are techniques available to compensate for springback and ensure the accuracy of metal bending operations.

Let Omnifab handle your metal bending orders

In conclusion, metal bending is essential to the realization of many types of industrial mechanical manufacturing projects. There are many different bending methods that require the use of specialized machine tools.

At Omnifab, we don’t hesitate to combine industrial welding, CNC and traditional machining with various metal cutting and bending techniques to create all kinds of parts and components that go into the machines we custom-design. We even offer a metal bending service designed to meet corporate needs.

So don’t hesitate to contact us for a mandate or to find out more!