Humans have been working with metals for thousands of years, mainly to make durable tools and objects. Today, there are a wide range of processes available to shape metals into the desired form.

At Omnifab, as a mechanical manufacturing company, we work with this material on a daily basis and have acquired an extensive knowledge about it. Today, we are pleased to share some of our sheet metal expertise with you.

What Is Sheet Metal?

As the name implies, sheet metal is metal that has been formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary greatly. However, it’s important to note that the terminology can change depending on the thickness. For example, we’ll use the term “metal plate” when referring to sheets thicker than 0.25″ (6mm).

As you might guess, the thinnest sheet metals are typically sold in rolls, while the thickest are sold in plate form.

Gauges: Useful for Determining Sheet Thickness

Generally speaking, the thickness of a steel plate is expressed in inches, while the thickness of a sheet is measured in gauges.

A larger gauge indicates a thinner material, while a smaller gauge indicates a thicker material. Note, however, that gauge thicknesses can vary from one metal to another.

Here’s a chart to help you better understand gauges:

| Gauge (ga) | Standard steel thickness (inches) | Galvanized steel thickness (inches) | Aluminum thickness (inches) |

| 3 | 0.2391 | 0.2294 | |

| 4 | 0.2242 | 0.2043 | |

| 5 | 0.2092 | 0.1819 | |

| 6 | 0.1943 | 0.1620 | |

| 7 | 0.1793 | 0.1443 | |

| 8 | 0.1644 | 0.1285 | |

| 9 | 0.1495 | 0.1532 | 0.1144 |

| 10 | 0.1345 | 0.1382 | 0.1019 |

| 11 | 0.1196 | 0.1233 | 0.0907 |

| 12 | 0.1046 | 0.1084 | 0.0808 |

| 13 | 0.0897 | 0.0934 | 0.0720 |

| 14 | 0.0747 | 0.0785 | 0.0641 |

| 15 | 0.0673 | 0.0710 | 0.0571 |

| 16 | 0.0598 | 0.0635 | 0.0508 |

| 17 | 0.0538 | 0.0575 | 0.0453 |

| 18 | 0.0478 | 0.0516 | 0.0403 |

| 19 | 0.0418 | 0.0456 | 0.0359 |

| 20 | 0.0359 | 0.0396 | 0.0320 |

| 21 | 0.0329 | 0.0366 | 0.0285 |

| 22 | 0.0299 | 0.0336 | 0.0253 |

| 23 | 0.0269 | 0.0306 | 0.0226 |

| 24 | 0.0239 | 0.0276 | 0.0201 |

| 25 | 0.0209 | 0.0247 | 0.0179 |

| 26 | 0.0179 | 0.0217 | 0.0159 |

| 27 | 0.0164 | 0.0202 | 0.0142 |

| 28 | 0.0149 | 0.0187 | 0.0126 |

| 29 | 0.0135 | 0.0172 | 0.0113 |

| 30 | 0.0120 | 0.0157 | 0.0100 |

| 31 | 0.0105 | 0.0142 | 0.0089 |

| 32 | 0.0097 | 0.0134 | 0.0080 |

| 33 | 0.0090 | 0.0071 | |

| 34 | 0.0082 | 0.0063 | |

| 35 | 0.0075 | 0.0056 | |

| 36 | 0.0067 |

Various Metals Commonly Cold in Sheet Form

1. CR Steel

CR (Cold Rolled) steel is a type of steel that offers greater bending consistency. It can be cold rolled to a thickness of 14GA (GA = Gauge) or less using cold rolling, while maintaining a smoother, more uniform surface than other materials. Once heat-pressed, it is cooled to room temperature before being rolled into sheets.

At Omnifab, we sometimes recommend CR steel because it offers:

- A highly refined result

- Accurate dimensions and well-defined lines

- Smooth surfaces that can be slightly oily to the touch

- High resistance to stress and deformation.

However, this steel is slightly more expensive than its cousin, HRPO steel.

2. HRPO steel

Like the previous steel, this one is hot rolled, hence the name HRPO: Hot Rolled Pickled and Oiled. The process involves treating it with very high heat, which can be over 1,700°F. When heated in this way, the steel becomes highly malleable and therefore easier to form. Typically, its thickness exceeds 14GA.

Our experts will recommend its use when you don’t need a flawless finish or very high dimensional accuracy. These criteria also make this steel more affordable than the more aesthetically pleasing CR steel.

3. Galvanized steel

Galvanizing is the process of applying a protective coating to steel. Typically, a zinc coating is applied to provide long-lasting protection against rust and corrosion. This is why galvanized steel is so popular: its corrosion resistance is up to 100 times better than that of uncoated steel.

Some benefits of choosing galvanized steel

- High corrosion resistance

- Low maintenance; economical in the long run

- Long service life

- No need for painting

4. Stainless Steel

Stainless steel is an alloy containing more than 10.5% chromium. This alloy makes it extremely resistant to corrosion. In addition to its anti-corrosive properties, stainless steel is an environmentally responsible alloy. Almost 90% of all stainless steel products are recycled.

Even after many years of use, stainless steel can be recycled indefinitely without any loss of quality. It is a durable, aesthetically pleasing, and resilient alloy with a wide range of applications.

6. Aluminum

There are various types of aluminum alloys. It can be alloyed with iron, zinc, copper, silicon and others. These different alloys give your metal different properties, such as greater resistance to oxidation. However, the primary purpose for these alloys is to enhance the mechanical strength of aluminum.

Aluminum is commonly recognized as a light, conductive, flexible and corrosion-resistant material.

Sheet Metal Processing

Sheet metal can be processed in several ways to achieve the desired result. Here are just a few examples:

Laser Cutting:

Laser metal cutting is an advanced manufacturing process that uses a focused laser beam to cut specific parts or shapes from sheet metal.

The laser generates intense heat that melts or vaporizes the metal material with great precision. This process can produce clean cuts, complex contours and fine details.

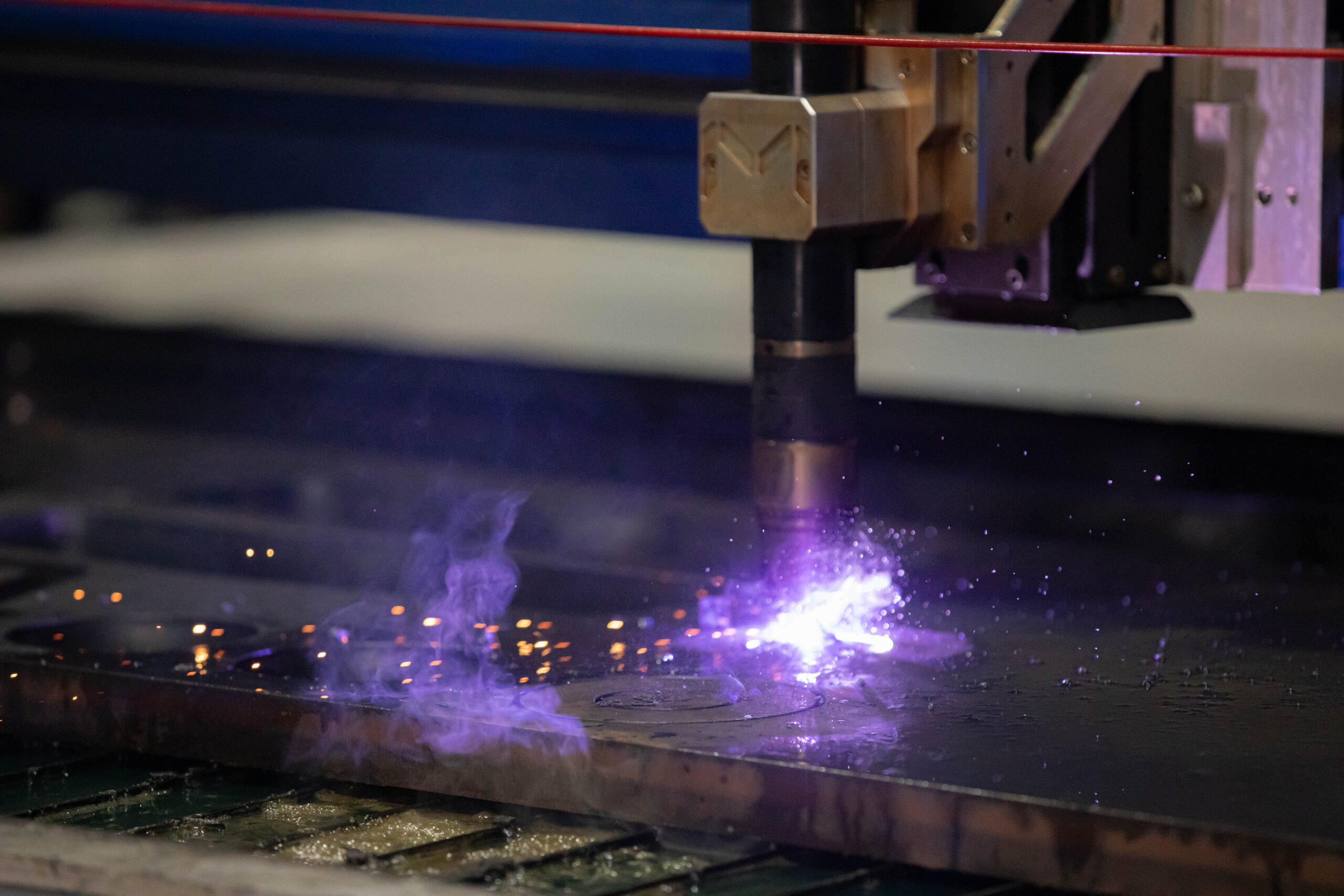

Plasma Cutting:

Plasma metal cutting is a manufacturing process that uses a jet of high-temperature plasma to cut metal parts. In this process, an inert gas is blown at high velocity through a nozzle, creating an electric arc with the metal part. This arc creates a very high temperature plasma that melts and ejects the metal material.

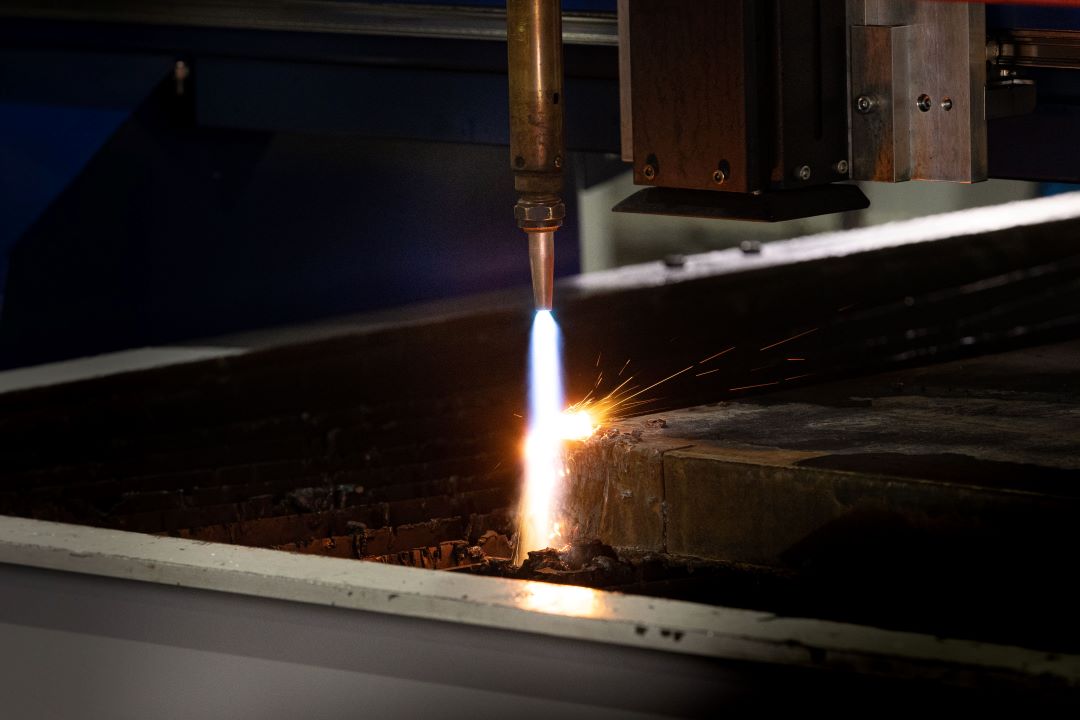

Oxyfuel Cutting:

Oxyfuel cutting is a thermal metal cutting method that uses a jet of pure oxygen sent over an area of metal brought to its melting point. This technique involves heating the workpiece to a very high temperature.

Interestingly, it is the chemical reaction between the pure oxygen and the steel (oxidation) that cuts the metal, not the power of the jet.

Bending:

Metal bending is the process of shaping metal plates or sheets into a predetermined form by applying a significant force, usually using a machine called a press brake. This force applies a stress above the elastic limit of the metal, allowing the material to physically deform without breaking.

Examples of Sheet Metal Applications

As you can see, the wide range of sheet metals available offers countless applications for your large projects. Our experts can provide the cutting and bending services you need.

Galvanized steel, for example, is ideal for roofs, chimneys, sheds, gutters, plumbing, bridges, pylons and more.

Stainless steel is used in many industries: food, chemical, pharmaceutical, cosmetics, etc. It is widely used in transportation, aeronautics and aerospace industries, as well as in everyday objects and in the architecture of our cities: buildings, bridges, pipes, cables, railings and handrails.

Satin finish steel products are used in a broad range of applications that require long-term, maintenance-free corrosion protection, such as bridges, industrial plants, recreation centers, utilities, oil refineries, petrochemical industries, automotive industry, and road construction – including railings, lighting, signage, and fencing.

At Omnifab, We Can Shape Sheet Metal to Meet Your Needs.

In short, the number of possible uses for sheet metal is virtually unlimited!

At Omnifab, we don’t hesitate to use different metal bending and cutting techniques to create all kinds of parts and components for industrial equipment.

So feel free to contact us, whether you want to entrust us with a project or simply find out more about our services.