Design, manufacture and installation of steel sole plates for an engine test bench

Home > Realisations > Design, manufacture and installation of steel sole plates for an engine test bench

At Omnifab we never hesitate to take on new projects, so we were delighted to be asked to design, manufacture and install steel base plates for a vehicle engine calibration test bench.

To make sure you understand what we’re talking about, we’ll start by explaining what a test bench is. Then we’ll explain in detail how we carried out this interesting job.

Electric motor test bench: Definition and Operation

As the name suggests, the purpose of a test bench is to test components or products in order to verify certain criteria. Test benches are essential to ensure the quality of mechanical products and to understand their behaviour under specific conditions.

In the case of our project, we are specifically interested in a test bench dedicated to the calibration of vehicle engines, such as trucks and buses. This specialised equipment is used to adjust and calibrate the operating parameters of power trains.

This type of test bench provides a controlled environment that allows engineers and technicians to observe engine performance with great precision by modulating various variables.

These test benches are particularly important for optimising and developing the engines that will power the vehicles of the future.

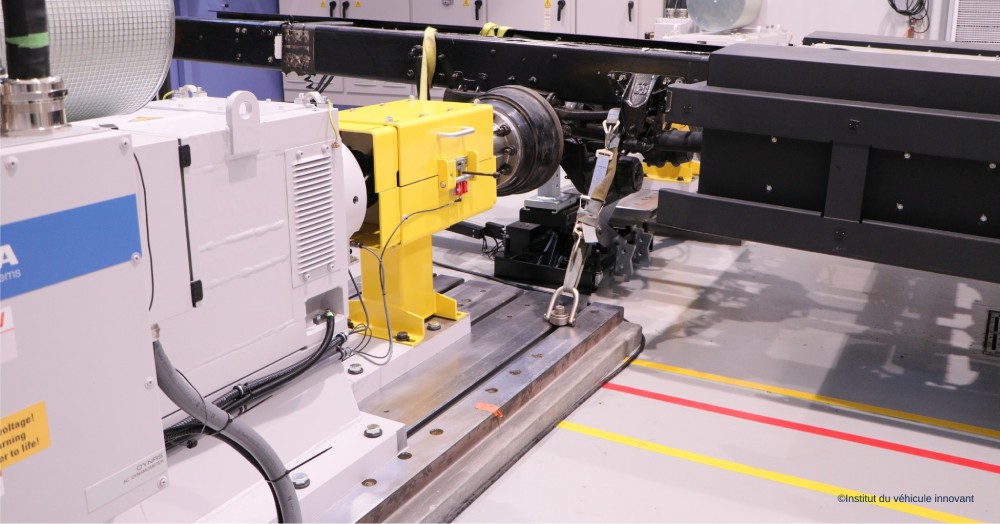

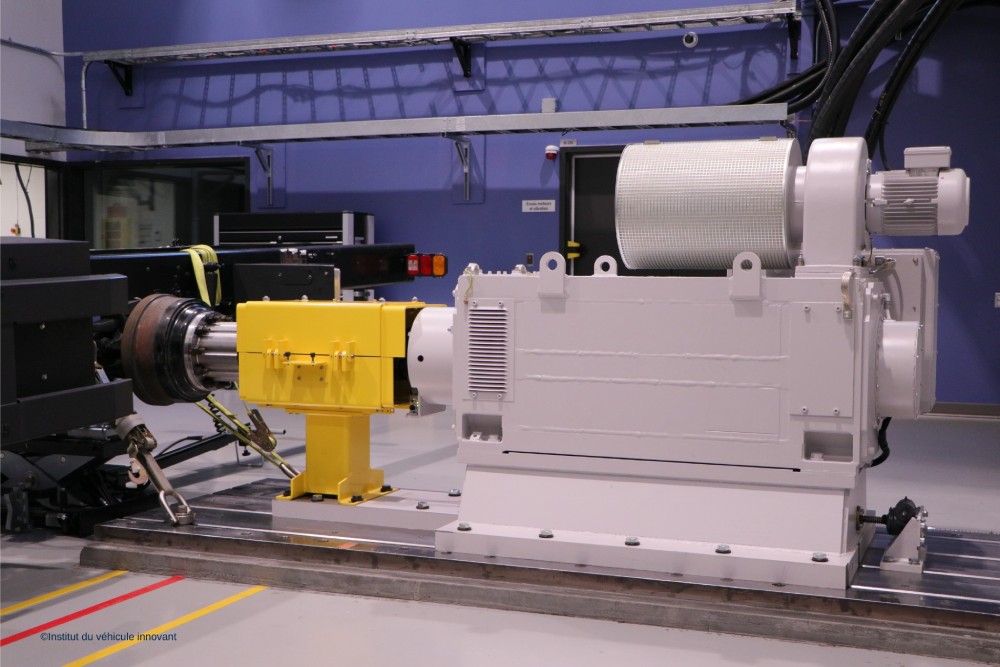

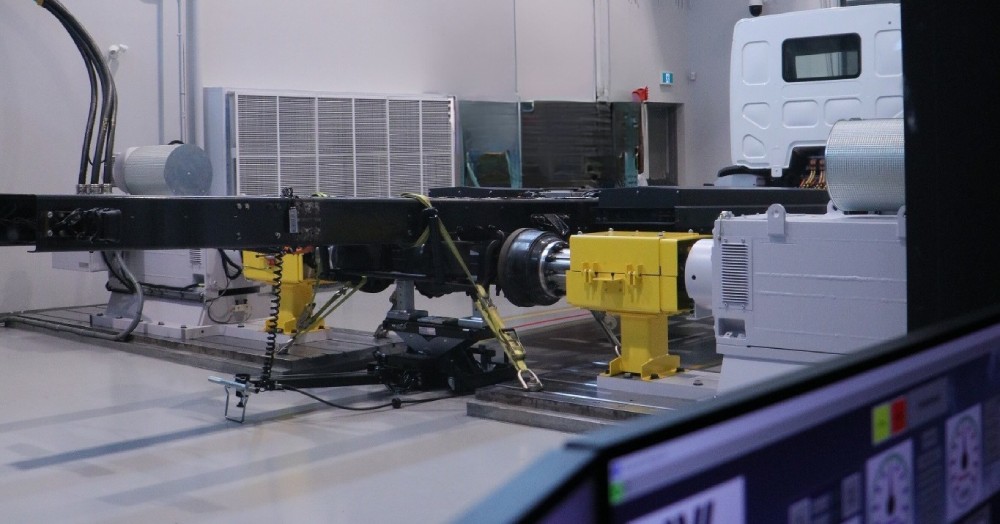

Photo Credit: Innovative Vehicle Institute – 2024

Some Applications of Vehicle Engine Test Benches:

- Engine parameter control: Enables the monitoring and adjustment of various engine parameters, such as fuel injection quantity, ignition timing, turbo pressure, power management, etc.

- Performance measurement: Allows the measurement of key performance metrics such as engine power, torque, fuel consumption, energy efficiency, range, emissions, acceleration response, etc.

- Driving condition simulation: Some test benches can simulate different driving conditions, including realistic scenarios such as acceleration, deceleration, uphill and downhill driving, etc.

- Detection of potential problems: Enables the identification of potential problems or performance defects before an engine goes into production.

- Fuel economy and emissions reduction Precise calibration optimises the engine for maximum efficiency in terms of fuel or battery consumption and reduces pollutant emissions for internal combustion engines.

- New engine development: Test benches are widely used in the development process of new engines to ensure they meet performance and regulatory standards.

Project Description: Fabrication of Steel Sole Plates for a Test Bench

Client Requirements

We were asked to design, manufacture and install two steel sole plates to form the foundation of a new engine test bench (dynamometer type) developed by the Innovative Vehicle Institute.

At the new facilities of this college-level technology transfer center, the team works on developing technologies that can be applied to electric buses and autonomous vehicles, among others.

Specific Constraints and Challenges

To complete this project, our engineering team had to meet specific tolerances in the manufacture and installation of the steel plates.

The two steel sole plates had to be extremely strong to support the considerable weight of the instruments and vehicles without deforming. In addition to this mass, the plates had to withstand the forces generated by the vehicles during calibration tests (often at full power).

It was also essential that both steel plates and the grooves in which they were mounted were perfectly level and aligned in the same plane in order to slide equipment over the plates and perform accurate tests on different vehicles.

Another key aspect of this project was the client’s request for the two plates to be designed in such a way that a third removable plate could easily be added between the first two.

Summary of the execution of the mandate

1 – Engineering

Once we had all the information, our team of industrial designers set about designing the part in accordance with the specific criteria given. In fact, the customer had provided an initial drawing that our mechanical engineering department revised to make it compliant, but also easy to manufacture.

Once the workshop drawings were complete, we submitted them to the client for approval. Following his consent, we started the manufacturing phase.

We can help you with your industrial project. Contact us!

2 – Making the two sole plates

To make the two large metal plates, our large-scale machining team used 3 ¼” Canadian (44W) mild steel plates. We machined them one by one on our largest milling machine, a Kiheung U1250.

3 – Installation on site

Using our custom flatbed truck, we first delivered the two steel plates, each weighing 5,625 pounds, to the customer.

There, a mobile team made up of several of our technicians spent a few days installing the 2 plates according to the rules of the trade. Here are some of the steps taken to ensure the plates were perfectly positioned and could not move during the tests:

- Installation

- Aligning and levelling

- Anchoring the footings to the concrete slab of the garage

- Pouring non-shrinking concrete under the sole plates

- Stripping and finishing

Throughout the installation process, our metrology partner, Alignement Beaudoin, ensured that the sole plates were positioned with the utmost precision.

Impact of the machined part on the client’s business

With the two soles perfectly in place, IVI can now carry out various tests to further its knowledge of engine technologies.

Machining can make a difference to YOUR business

As a company, we are very proud to support other professionals in successfully completing their projects. Sometimes, having custom parts designed and manufactured can truly make a big difference for your business. Don’t hesitate to contact us if you have a project in mind—we can make it happen!