As you likely already know, metals and alloys are raw materials that are often sold in sheet, plate or tube form. As such, these raw materials need to be cut to produce parts with specific shapes.

Obviously, metal cannot be shaped using any cutting technique. One highly effective technique is plasma cutting: a process you’ll learn a lot about in this text.

In the following sections, you’ll find information on how it works, its benefits, and the industries that use it! But let’s start with its definition!

Brief Definition of Plasma Cutting

Plasma cutting (plasma arc cutting) is a fusion metal cutting process that uses a jet of ionized gas at temperatures approaching 20,000°C to melt and expel the material from the cut.

This process was originally developed to cut materials that could not be satisfactorily handled by the oxyfuel cutting process.

Plasma cutting should not be confused with oxyfuel or laser cutting.

The Principle of Plasma Cutting

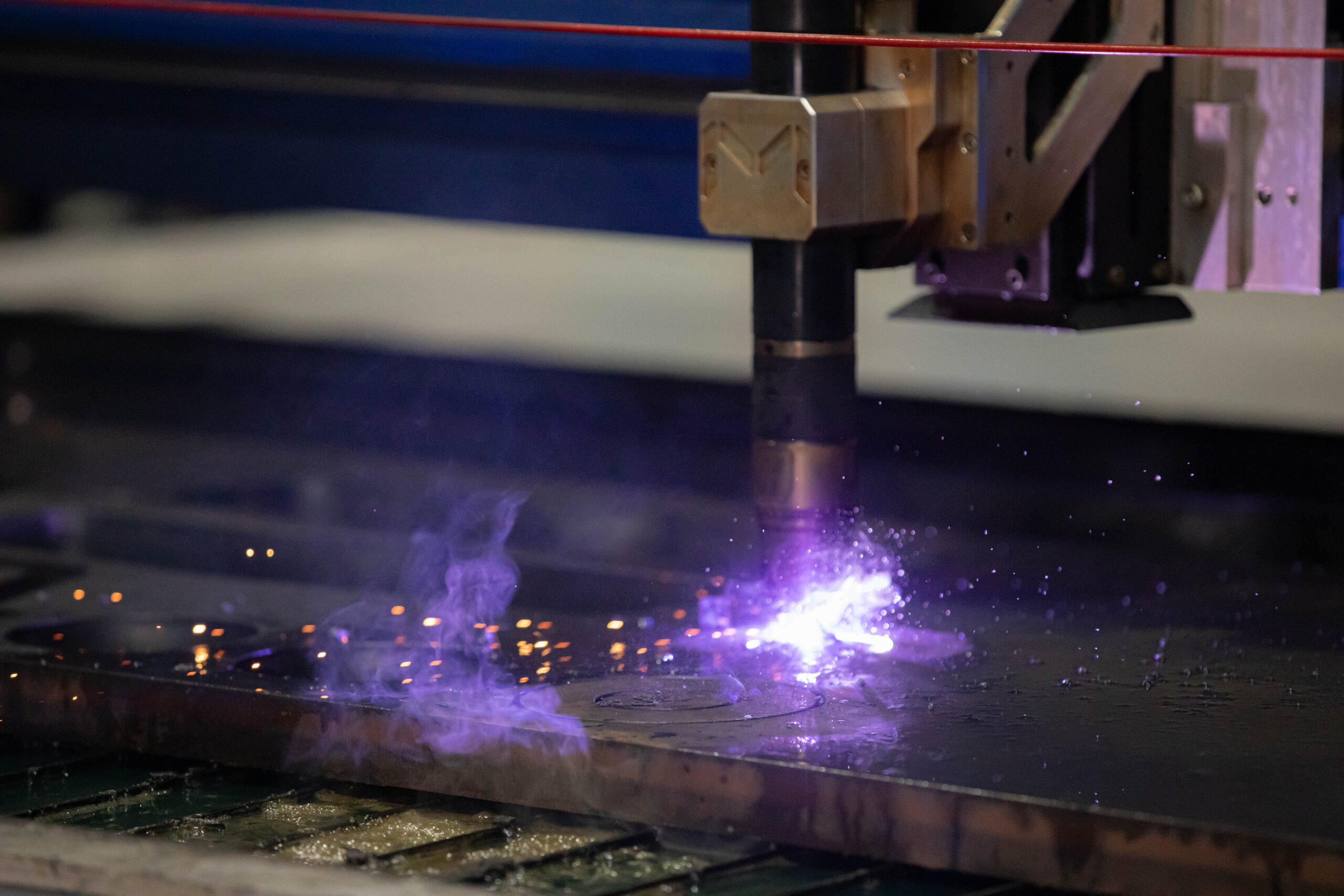

In plasma cutting, an electric arc is ignited between an electrode (cathode) and the workpiece (anode). The electrode is encased in a gas nozzle that is cooled by either water or gas, which constricts the arc and creates a plasma jet (plasma is considered the 4th state of matter: a highly concentrated, narrow ionized gas) at high temperature and speed.

When the plasma jet strikes the workpiece, the heat melts the metal and the gas stream expels molten material from the cut.

The torch used for plasma cutting can be either manually operated or mounted on a machine that allows it to be moved with greater precision. The latter is commonly referred to as a plasma cutting table.

Plasma Gases

Plasma gases (used for plasma cutting) are generally air, oxygen, argon, argon/hydrogen mix or nitrogen.

However, as with welding gases, the preferred gas for plasma cutting varies depending on the metal. For example, oxygen is effective for cutting standard steel, but nitrogen, argon and hydrogen offer excellent performance when cutting stainless steel.

CNC Plasma Cutting

Some manufacturers of plasma cutting equipment produce CNC (computer numerically controlled) cutting tables.

CNC tables enable a computer to control the movement of torch head, ensuring clean, precise cuts. Modern CNC plasma cutting machines are capable of cutting materials along multiple axes.

Contact our plasma cutting experts

Industries That Use Plasma Cutting

Plasma cutting is widely used in industrial sectors where balancing cost and cutting speed is critical. This explains why the technique is widely used in industries such as

- Industrial mechanical manufacturing

- Construction and architecture

- Refrigeration, air conditioning and ventilation

- Steel industry

- Automotive industry

- Shipbuilding

- Power generation.

The Benefits of Plasma Cutting

Depending on the metal cutting project to be completed, there may be several advantages to choosing plasma cutting:

- Precise cuts and very straight cut surfaces;

- High cutting speeds;

- Minimal heat transfer to the cut material, reducing distortion;

- Excellent repeatability (especially with CNC plasma cutters);

- Cost-effective and energy-efficient technology.

Materials That Can Be Cut with Plasma

The plasma arc can cut a very wide range of alloys and electrically conductive metals, including

- Carbon steels

- Stainless steels

- Aluminum and its alloys

- Nickel alloys

- Copper alloys

- Titanium.

These materials can be in the form of sheets, plates, tubes, and more.

Omnifab: Plasma Cutting Expertise at Your Service

In short, plasma cutting is a manufacturing process that’s definitely worth considering when it comes to sheet metal cutting. Depending on the material being cut, its thickness and other factors, this technique can offer significant savings in time and resources.

At Omnifab, we confidently use this technique to produce a wide variety of metal parts for the industrial machinery we design. We also offer a plasma cutting service tailored to meet the specific needs of companies in Quebec, Canada and the northeastern United States.

Don’t hesitate to contact our team to learn more!